The Importance of Precision Molds in Metal Fabrication

Precision molds are essential components in the metal fabrication industry, serving as the backbone for a vast array of products we encounter in our daily lives. These molds are meticulously engineered to create high-quality parts and components, ensuring that they meet stringent specifications. In this article, we will delve deep into the significance of precision molds, their types, applications, and how they contribute to creating superior metal products.

What Are Precision Molds?

Precision molds are specialized tools designed to shape molten materials into desired forms with utmost accuracy. They play a pivotal role in processes such as injection molding and casting, wherein raw materials are transformed into finished products. The precise engineering of these molds enables manufacturers to produce parts that are not only functional but also aesthetically pleasing.

The Process of Creating Precision Molds

The creation of precision molds involves several critical steps:

- Design Phase: The process begins with engineers designing the mold using advanced CAD software. This design must account for the dimensions, tolerances, and any complex features necessary for the final product.

- Material Selection: The right materials are pivotal in making durable molds. Common materials include steel, aluminum, and certain alloys, each chosen based on the project’s specific requirements.

- Machining: Skilled machinists utilize CNC (Computer Numerical Control) machines to manufacture the mold parts with high precision. This step is crucial for achieving the exact specifications dictated by the design.

- Assembly: Once the parts are fabricated, they are assembled into a complete mold. Attention to detail during this phase ensures that all components fit seamlessly together.

- Testing: Before the mold goes into full production, it undergoes rigorous testing to ensure it meets quality standards and performs as intended.

Types of Precision Molds

Understanding the different types of precision molds is essential for organizations looking to implement effective metal fabrication techniques. Here, we explore the primary types:

1. Injection Molds

Injection molds are used to produce parts by injecting molten material into the mold cavity. They are often utilized for creating plastic components but can also be adapted for metals. The advantages include:

- High production efficiency

- Ability to produce intricate features

- Minimal waste generation

2. Blow Molds

Blow molds are particularly favored for creating hollow parts, such as bottles and containers. The process involves inflating a hot, tube-like piece of material inside a mold to achieve the desired shape. Key benefits include:

- Production of lightweight and durable products

- Versatility in design

- Cost-effectiveness for large quantities

3. Compression Molds

Compression molding is used for high-precision components, often in the automotive and aerospace industries. This traditional yet effective technique allows for:

- Great control over material properties

- Effective use of thermoplastic and thermosetting materials

- Enhanced surface finishes

4. Die Casting Molds

Die casting molds are typically associated with non-ferrous metals, such as aluminum and zinc. This process involves injecting molten metal into a mold under high pressure, leading to components characterized by:

- Excellent dimensional accuracy

- Smooth surface finishes

- High production rates

Applications of Precision Molds in Various Industries

Precision molds are used across various sectors, reflecting their versatility and importance. Below, we discuss some of the key industries that benefit from these molds:

Aerospace Industry

In aerospace manufacturing, the need for precise tolerances is paramount. Here, precision molds are employed to produce components that must withstand extreme stress and temperature variations during flight. The use of advanced mold-making techniques ensures that aerospace parts, such as turbine blades and fuselage components, meet stringent regulatory standards.

Automotive Sector

The automotive industry relies heavily on precision molds for producing everything from intricate interior components to robust engine parts. With the push for lightweight materials and improved fuel efficiency, precision molds help create parts that are not only functional but also contribute to the overall performance and safety of vehicles.

Consumer Electronics

As consumer electronics continue to evolve, the demand for high-precision components has skyrocketed. Devices such as smartphones, tablets, and laptops require parts made with precision molds to ensure reliability and performance. The aesthetics of these devices, often shaped by their molded components, also play a crucial role in consumer choice.

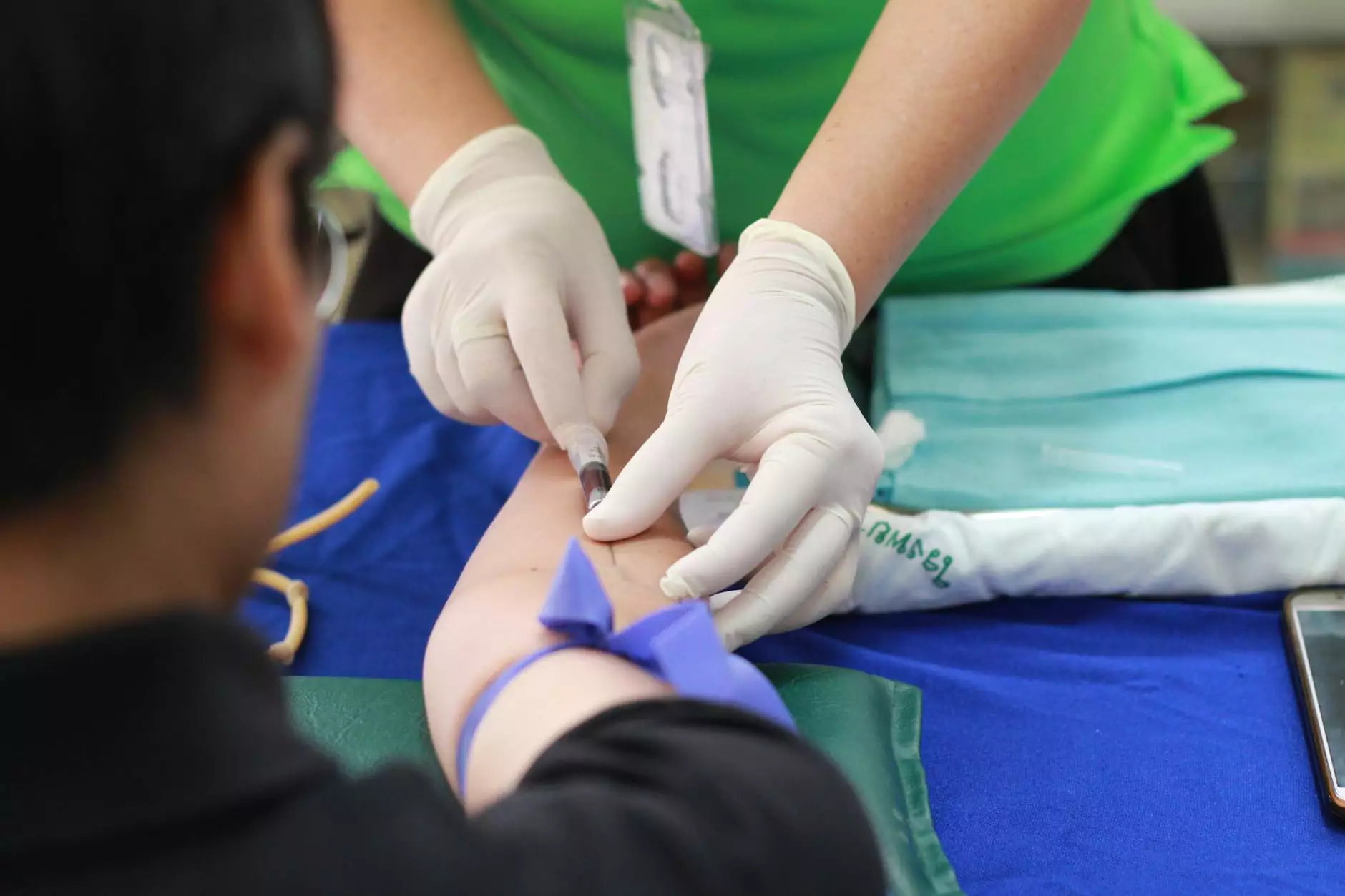

Medical Devices

In the medical industry, precision is non-negotiable. Medical devices such as syringes, implantables, and diagnostic equipment are produced using high-quality precision molds. This guarantees that the products are not only effective but also safe for patients.

The Benefits of Using Precision Molds

Investing in precision molds comes with a range of benefits that can significantly enhance production processes:

- Cost Efficiency: While the initial investment may be high, precision molds enable streamlined manufacturing which reduces costs in the long run through increased production rates and minimized waste.

- Enhanced Quality: The high accuracy of molds leads to superior product quality, reducing the chances of defects and reworks which are costly and time-consuming.

- Shorter Lead Times: With efficient mold designs, manufacturers can produce parts faster, allowing them to respond more quickly to market demands.

- Customization: Precision molds can be custom-made to fit unique production needs, giving businesses the flexibility to innovate and produce bespoke products.

Conclusion

As we've explored, precision molds play a critical role in the metal fabrication landscape. They not only enhance efficiency and quality but also allow businesses across various industries to innovate and meet consumer demands. With continuous advancements in mold technology and design, the future looks promising for precision molds and their application in manufacturing.

For companies in need of high-quality precision molds, turning to experts in the field is vital. At Deep Mould, we specialize in creating custom precision molds tailored to meet the specific requirements of our clients. With a commitment to quality and innovation, we are dedicated to helping businesses thrive in a competitive market.